Crane Hook Block Twisting

Johnson gunnebo 75 ton five sheave hook block with 3 4 sheaves.

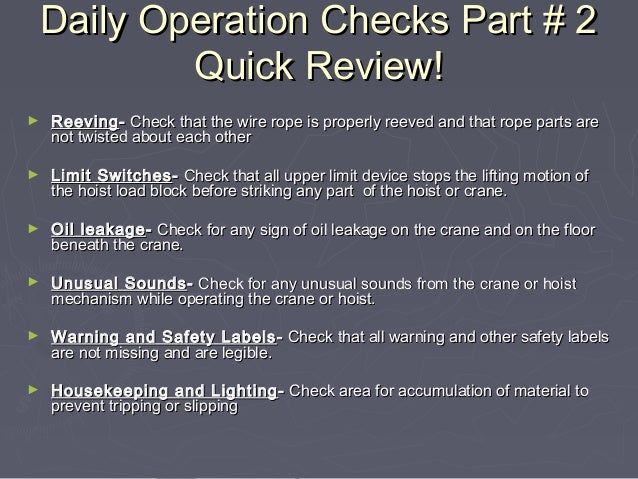

Crane hook block twisting. Standard capacities to 300t design factor 4 1 larger capacities available sheaves from 8 to 36 details of crane hook block twisting. Cabling of the block occurs most frequently as the load in the wire rope is released and the falls are in a lowered position. With time the wire rope will eventually suffer from block twisting or rope distortion. Hook blocks for sale and rent.

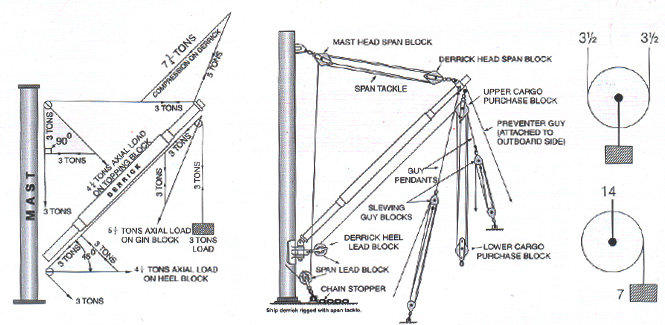

A crane hook attached directly to the hoist ropes would cause the ropes to twist if the load was turned from its original orientation. Per din 15401 or din 15402 other hook standards available heavy duty thrust bearing dual motion swing. If the block is misaligned it will induce twist into the rope during operation by the rope climbing the flange or rolling into the sheaves of the travelling block. Capacity of crane hook block twisting.

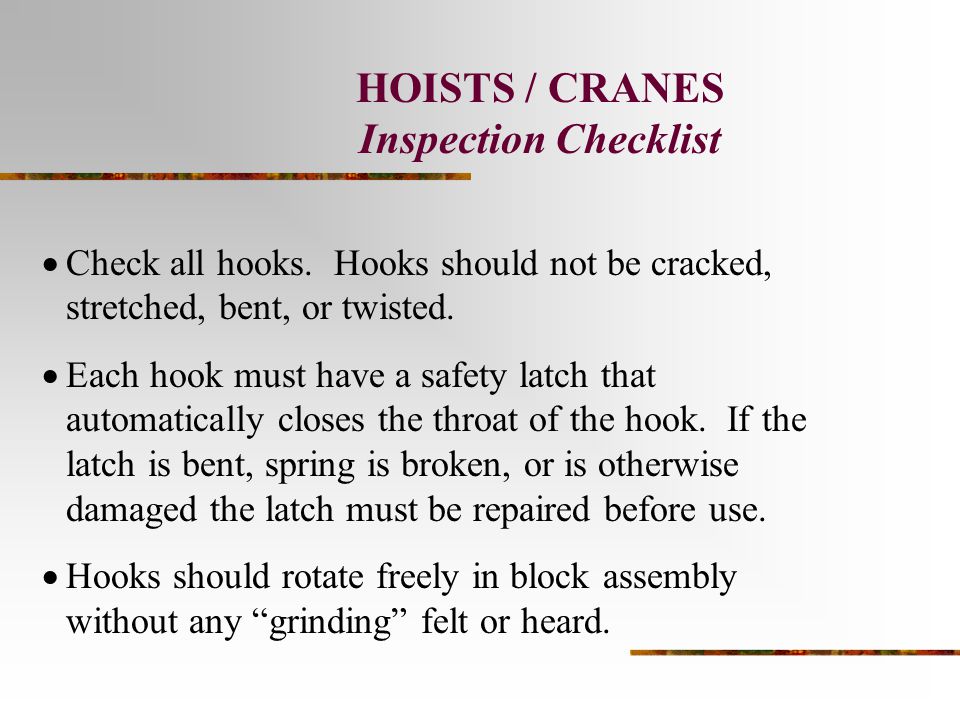

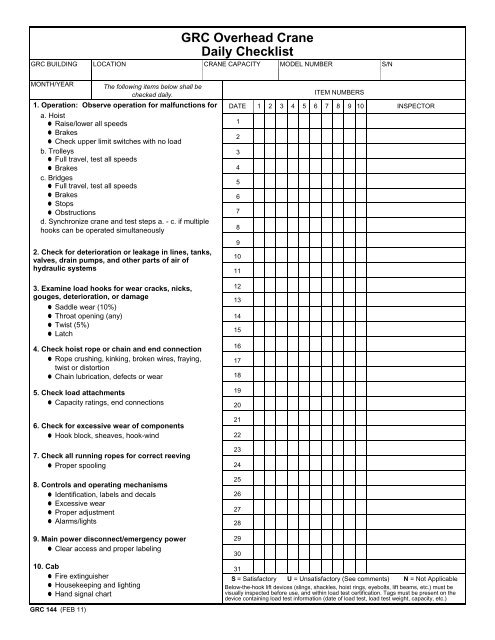

See all parts for sale on the crane network a leader in hook block sales. Other types of crane hooks. Crane hook block twisting. The hook shank bearing and nut are mechanical components which are not accessible to visual or ndt inspection without disassembly.

According to different standards crane hooks can be classified into different types the single and double hook the forging and laminated hook closed and semi closed hook and other hooks such as electric rotary hook etc. Per din 15401 or din 15402 other hook standards available heavy duty thrust bearing dual motion swing. Each time a load is applied to a wire rope it will slightly twist or unlay. Crane 1 non destructive testing of crane hooks.

Using a rope that has been cabled is dangerous and unsafe for workers. Cabling may be considered as the twisting of the block beyond one half revolution 180o twisting of the traveling block. Capacity of crane hook block twisting. Over 30 000 companies and individuals rely on our online services to effectively manage their fleet for the sale.

This would have a number of undesirable effects such as over stressing the ropes and boom pulleys creating an unbalanced load and causing the load to swing back in an uncontrolled fashion when released. The hook shank is the part of the hook that transfers the load to the hook block and is supported within the body of the block by a rotating bearing. If a block is operated with odd part reeving 3 5 7 etc and its rope termination point is at the side of the block it will not hang plumb. Standard capacities to 300t design factor 4 1 larger capacities available sheaves from 8 to 36 details of crane hook block twisting.