Creo Sheet Metal K Factor

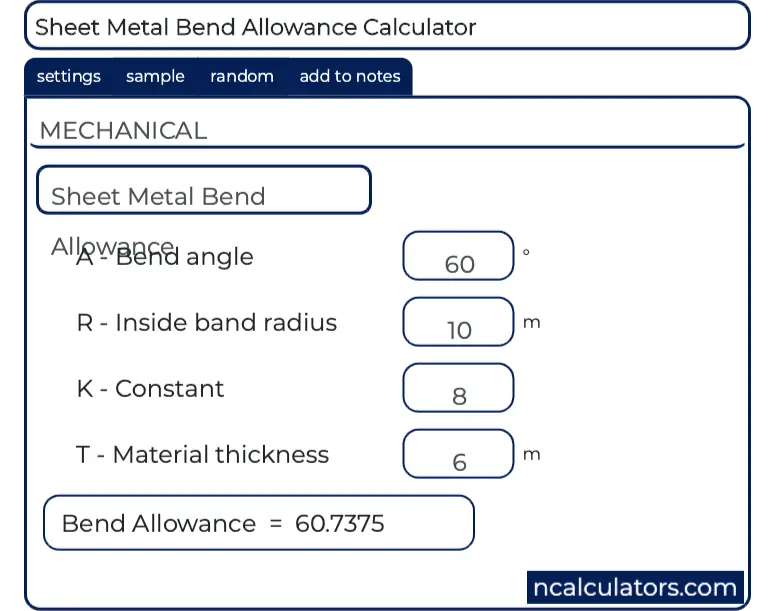

In this article we will discuss sheetmetal bend deduction bend allowance k factor y factor and sheet metal flat pattern calculations.

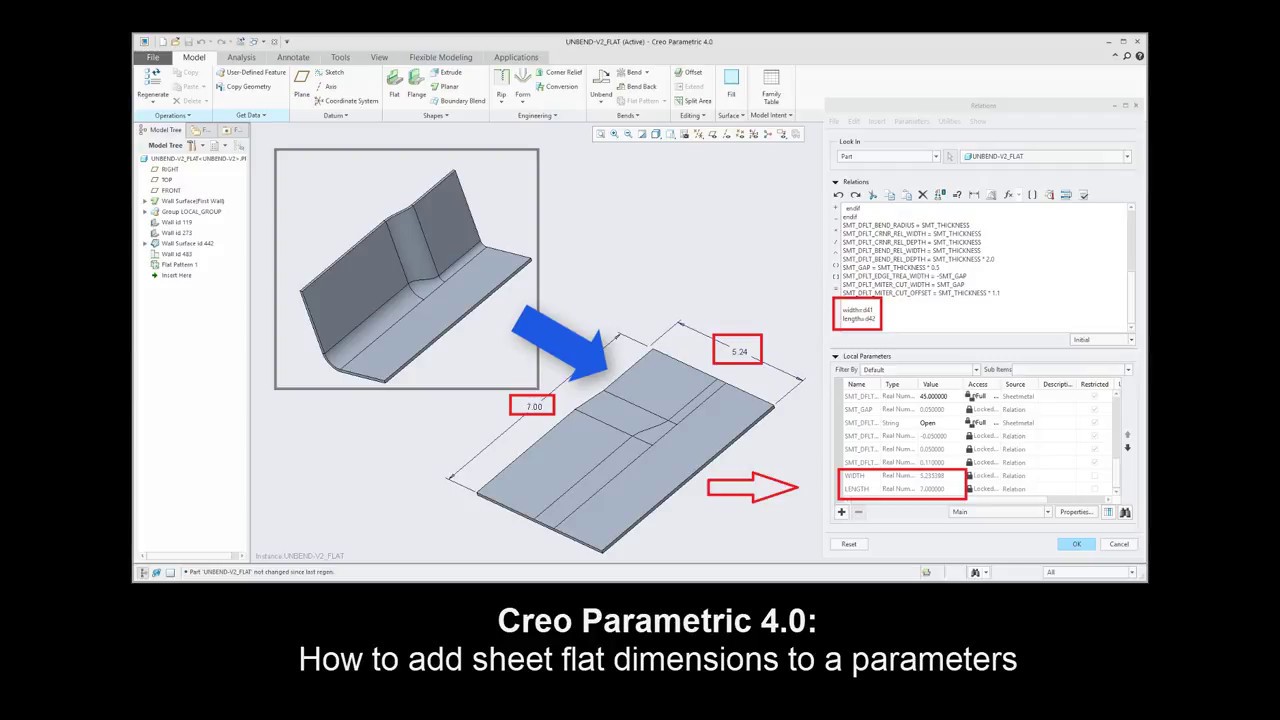

Creo sheet metal k factor. The location of the neutral axis varies and is based on the material s physical properties and its thickness. Calculate k factor bend allowance and y factor for sheet metal bending. Reference pages explaining k factor and y factor. With a y factor of 5 creo default the flat pattern ws 7 0354 long.

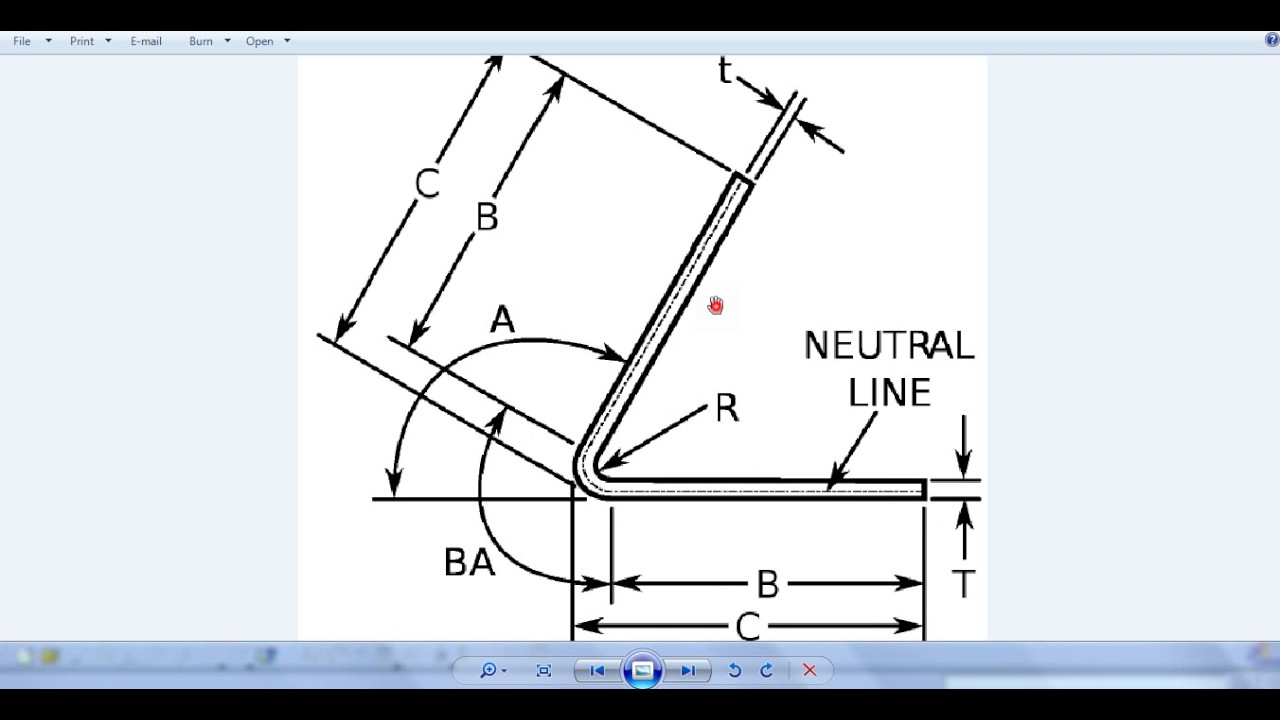

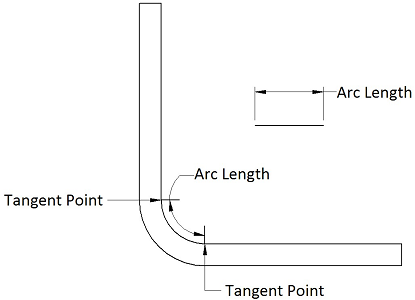

When you bend sheet metal the neutral axis shifts toward the inside surface of the bend. Creo sheet metal tutorial. Creating feature specific bend allowance using the bend allowance tab of sheet metal tools when available. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness.

Using a variety of y and k factor bend allowance calculations designers can create flat patterns of the designs. The k factor is defined as the ratio between the material thickness t and the neutral fibre axis t i e. K factor is an import. Sheet metal k factor hi graham i could be wrong for the latest creo 1 0 but till now i have never able to directly access that smt k factor system parameter with relations.

The result is parametric fully associative solid models of sheet metal parts and assemblies. The line where the transition from compression to stretching occurs is called the neutral axis. Smt part bend allowance factor sets the value of y factor or k factor. Overview this comprehensive suite of creo sheet metal design tools helps users create features such as walls bends punches notches forms and relief features.

This video to describe setting of k factor in creo and how to change developed length of sheet metal parts. I had a question on k factors for our 3 d modeling software. The k factor is the most important and elusive variable of bending because it varies both as a function of the material and according to parameters such as angle and tooling. Our design engineers typically use a factor of 0 4 for our air formed press brake parts.

When metal is bent the top section is going to undergo compression and the bottom section will be stretched. K factor in sheet metal bending is a constant used to calculate sheet metal flat length or flat pattern. The part of the material that bends without being compressed nor elongated. These parameters can also be set using the bend allowance area of the sheetmetal preferences dialog box.

K factor a constant determined by dividing the thickness of the sheet by the location of the neutral axis which is the part of sheet metal that does not change length.