Curamik Ceramic Substrates

Contact our sales specialists for further information about curamik advantage.

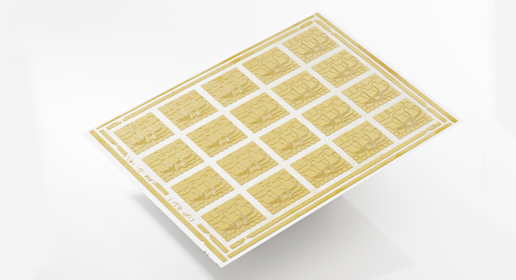

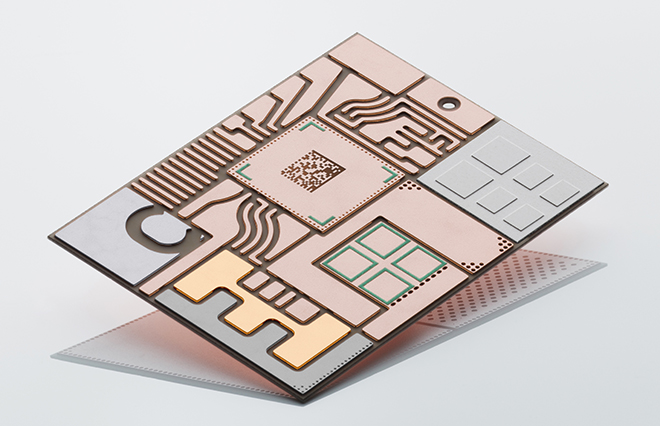

Curamik ceramic substrates. At ceramic substrates we operate with a bank of nine cnc s twelve traditional lathes and mills producing fully engineered machinable ceramic components six days a week. Our curamik performance substrates are based on si 3 n 4 ceramics joined with copper by active metal brazing amb. Global dbc ceramic substrate market 2020 rogers curamik germany kcc korea ferrotec shanghai shenhe thermo magnetics electronics china sourabhkshirsagardm uncategorized april 27 2020 2 minutes. Useable area 127 mm x 178 mm 0 05 copper peeling strength 4 0 n mm 50 mm min for dbc with 0 3 mm cu thickness 10 0 n mm 50 mm min for amb with 0 5 mm cu thickness platings electroless ni.

Curamik ceramic substrates technical data sheet total dimensions master card 138 mm x 190 5 mm 1 5 max. 3 µm 7 µm 8 2 p all. The low coefficient of thermal expansion of the ceramic substrate means they outperform substrates based on metal or plastic. These substrates offer a longer lifetime and greater reliability and performance than alumina substrates and it comes at a competitive price point.

Partial discharge free substrates free of partial discharge for power modules 1 7 kv. Download the complete technical data sheet with all curamik advantage features. Curamik high temperature high voltage substrates consist of pure copper bonded to a ceramic substrate such as al2o3 alumina aln aluminum nitride hps zro2 doped or silicon based si3n4 silicon nitride. Maruwa rogers curamik coorstek toshiba materials icp technology ferrotec kcc corporation and others currency validating machine market to witness robust expansion by 2026 with top key players like crane payment innovations cummins allison glory global solutions japan cash machine.

Our curamik thermal substrates offer the best thermal conductivity in the industry. The substrates ain direct bond copper dbc provides an adjusted thermal expansion coefficient which is closer to that of silicon and results in little tension in the solder layer between chip and substrate. Our curamik ceramic substrates offer high heat conductivity high heat capacity and thermal spreading of the substrates thick copper cladding making our substrates indispensable to power electronics. Aln ceramic substrates market globally by 2025.

Dbc direct bond copper a high tem. Our curamik power plus substrates are based on zr doped al 2 o 3 hps ceramic. The doping process provides enhanced robustness and improved properties when exposed to mechanical constraints.