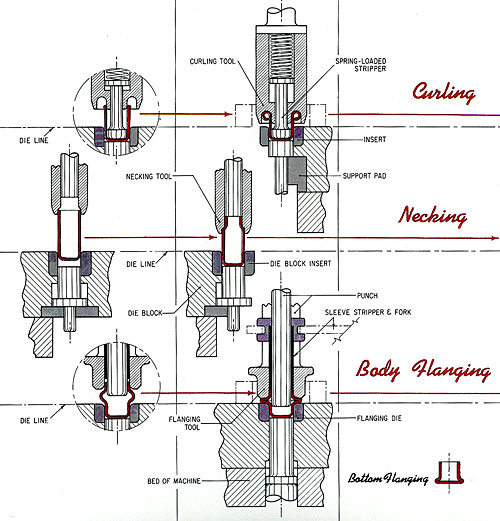

Curling Operation In Sheet Metal

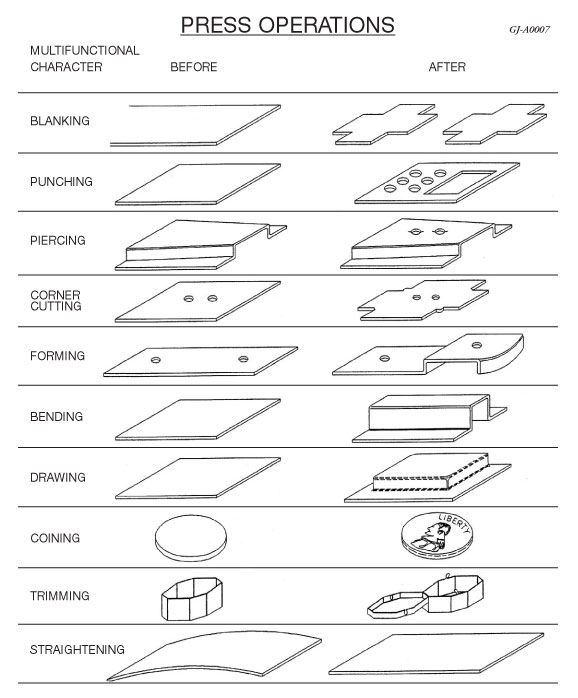

Curling channel u bending air bending offset bending corrugating and tube forming.

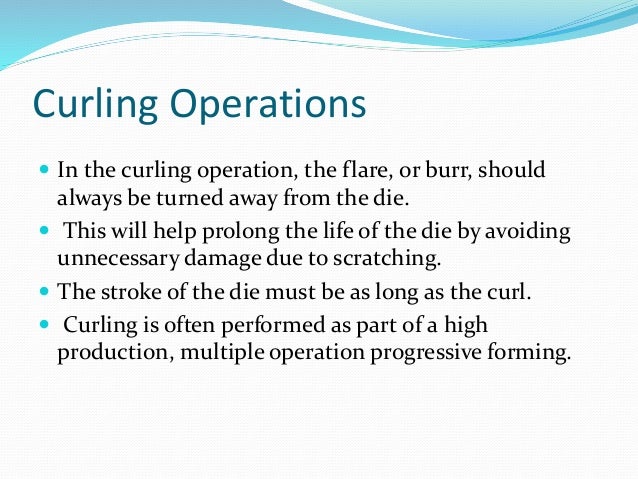

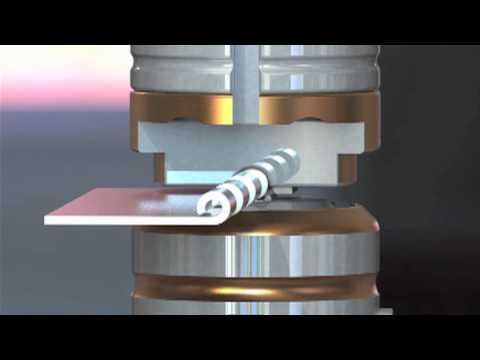

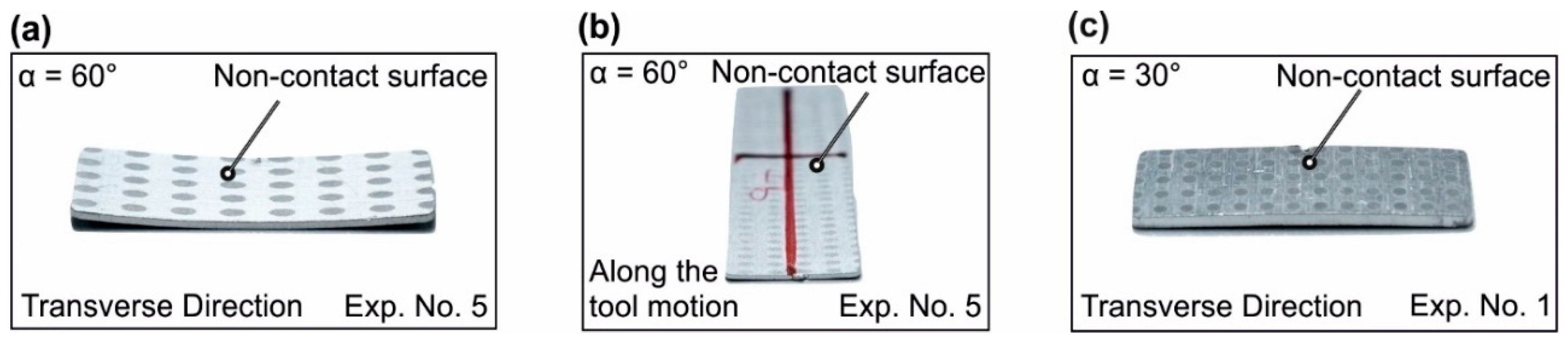

Curling operation in sheet metal. Curls are features that are produced by rolling the edge of a stamped sheet metal part. This operation is sometimes called false wiring. Curls are produced in order to shape the material into a hollow ring. Curling is a sheet metal forming process that s used to smooth out the otherwise sharp and rugged edges of sheet metal.

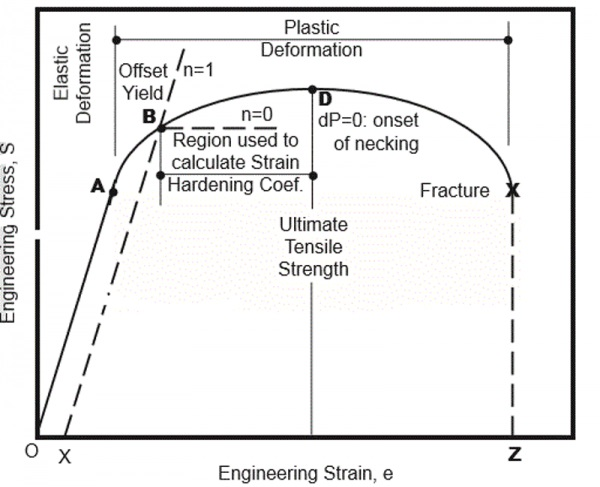

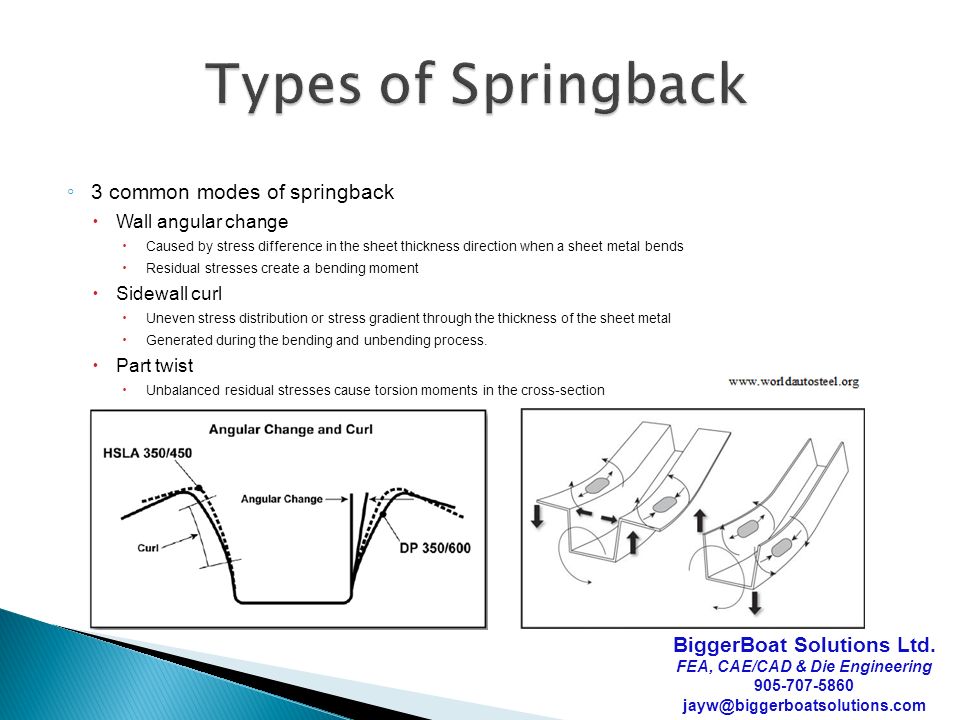

Sheet metalworking cutting and forming thin sheets of metal usually performed as cold working sheet metal 0 4 1 64 to 6 mm 1 4in. These curls should generally have a diameter of about 10 to 20 times the thickness of the material being worked. Curling is different than a tear drop hem because in a curl the edge finishes inside itself where a hem leaves the initial edge exposed. Sheet bending sheet bending is defined as the straining of the.

Curling is a forming process that involves de burring sheet metal to produce smooth edges. Sheet metal often contains sharp edges with burrs after it s initially produced. Curling can be performed to eliminate sharp edges and increase the moment of inertia near the curled end. Curling is a sheet metal forming process used to form the edges into a hollow ring.

Curling can be performed to eliminate sharp edges and increase the moment of inertianear the curled end. Other parts are curled to perform their primary function such as door hinges. Curling curling sheet metal is the process of adding a hollow circular roll to the edge of the sheet. The curled edge provides strength to the edge and makes it safe for handling.

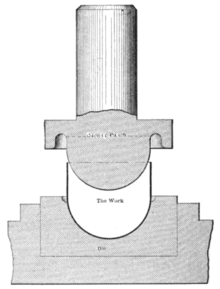

Curling the forming of an edge having a circular cross section along a sheet or around the end of a shell or tube. This is normally done to eliminate sharp edges.